A brightly coloured tray for hotdogs; a silver- and gold-embossed box for a perfume; sturdy packaging for a ceramic jug; a lightweight container for sushi… Today, all manner of packaging can be ordered online with the design of your choice and delivered within 48 hours. What’s more, small minimum print runs make this technology ideal for limited editions or themed products.

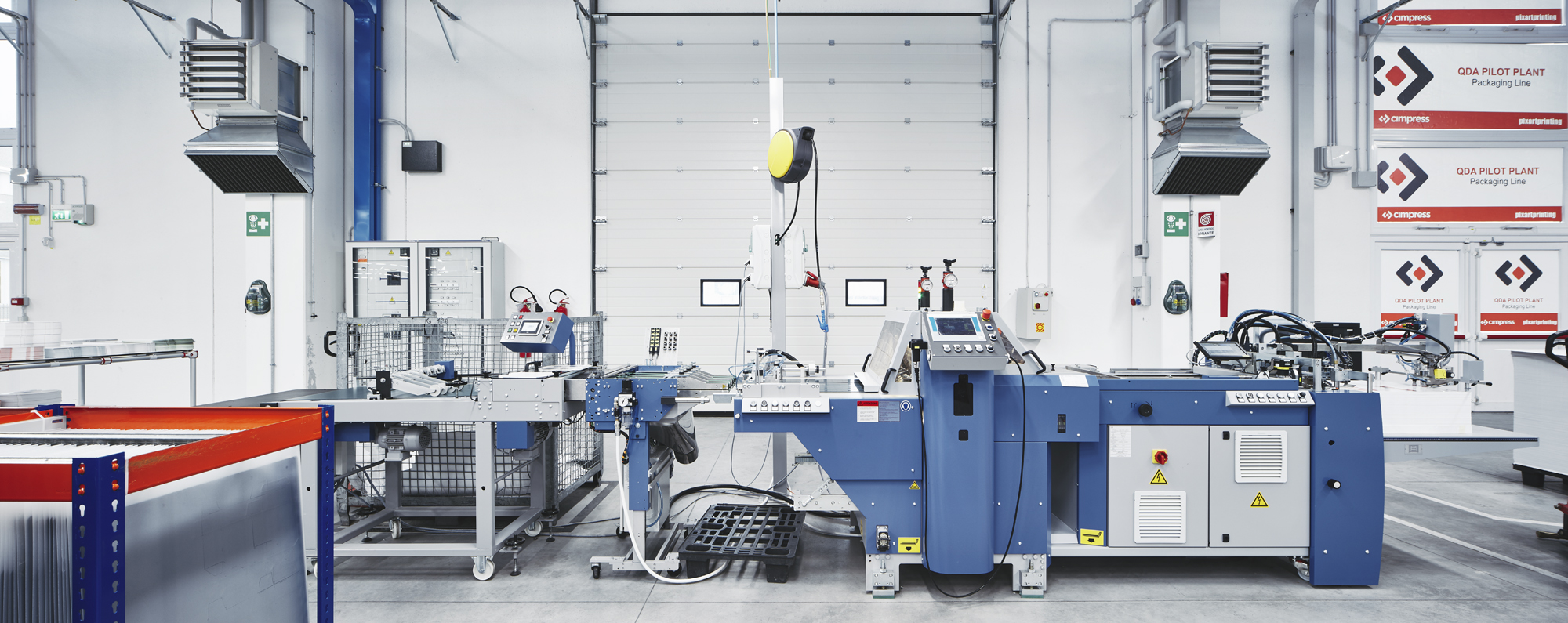

This possibility (long-dreamt of by small businesses, marketing agencies and event organisers, to name but a few) has been a click away since February 2017, when here at Pixartprinting (the online printing specialist, part of the Cimpress Group) we launched Catalyst technology. In our Quarto d’Altino plant, a line of next-generation machines is taking custom packaging to a new level. They’re part of a highly automated workflow that is managed by software specially developed in house.

Before this technology, creating a custom box wasn’t easy. Food and beverage firms, photographers, marketing agencies and other businesses often require special packaging with a whole host of shapes, colours, uses and contents. In the past, they had to use printers which, after a lengthy production process, would then deliver hundreds of standardised and anonymous boxes.

But today packaging is much more than just a container. It’s that part of the product which comes into direct visual and physical contact with the consumer. It’s also what makes a product stand out from the others on the shelf.

Catalyst is a game changer: it brings quick and easy access to custom packaging to customers for whom it was previously out of reach. Everything is done online. Our web-to-print (W2P) system lets customers submit their design over the Internet and receive their custom-printed packaging through the post.

But there’s more. Often, as we mentioned in the article on packaging design, the purpose of on-demand packaging is often a limited edition, the box for a themed item or a sample. Before, printers would require a minimum print run to cover set-up costs. This meant that customers would have to buy dozens of boxes that they didn’t need. But Catalyst is so flexible that minimum print runs start at 25. What’s more, the system is ideally suited to nimble SMEs: delivery times can be as short as 48 hours.

Last but not least, Catalyst offers a range of over 300 formats, sizes and customisation options: flip-lid promotional boxes, takeaway boxes, paperboard boxes with windows for showing or accessing contents, boxes with reinforced bases, oval boxes, pull-out boxes, ring boxes and more. Also available are food containers that can be microwaved and frozen, with food-safe inks and oil- and water-resistant coatings: trays, pots, lunch boxes, sandwich boxes, takeaway boxes with flap or gables… All of them with the customer’s design.

And if that wasn’t enough, Catalyst adds a third dimension to the box’s surface. The Scodix machine enables customers to use raised-ink printing in their graphics. This finish lends a seductive tactile effect to packaging. Catalyst also allows silver or gold effects to be applied to packaging for a luxurious touch. Lastly, customers can choose boxes reinforced with a cardboard structure to protect against bumping and crushing.

The Catalyst production line is a based on a clever mix of leading-edge technologies and is controlled by specially developed software: an HP Indigo 30000 digital press, a Harris & Bruno ExcelCoat ZR30 coater, a Bograma BSR 550 Servo Rotary die-cutter, a module for silver- and gold-effect laminating, a Kama Flexfold 52i folder-gluer and a Tecnomac Evolution 3 laminating machine. Thanks to Catalyst, custom packaging has never been so easy.